My First Printer

I wanted to get into 3D printing about the first time I saw a 3D printer. The only problem was, they were rather expensive and you have to build them and calibrate them (and calibrate them and calibrate them). It wasn't worth the investment for me to purchase something that may just continuously frustrate me. Sure there were pre-built machines for purchase, but their price tag was far greater than the DIY kits.

About 3 years ago, I was made aware of an Indiegogo campaeign from a company called New Matter. They were looking to fund an affordable 3D printer that was a push button solution. I didn't really care about their 3D printing store idea, but rather getting in on their "Early Bird Special." This would allow me to have a fully assembled 3D printer for under $200 shipped. It was a gamble, but the backer tiers were quickly selling out and the campaign quickly reached it's goal. Then I waited and almost forgot about the printer I supported until it shipped on October 15, 2015.

First Impressions

When I first received the printer, I was impressed by the packaging. It was fully assembled and ready to go when taken out of the box. However, with all of this packaging, the cardboard was still incredibly thin and it resulted in my acrylic cover being damaged. I reported it and had a new cover shipped to me, but a little super glue fixed the damaged one. There was absolutely no software in the box, but it had a placard with instructions to their website. Once there, I downloaded their application and was one my way to my first print. All in all my experience was pleasant and I knew that I was one of the first to receive my printer. I was a guinea pig after all and wanted to do my part to flush out any bugs; and there were plenty of bugs.

Despite this wonderful packaging, the cover was victim to damage

Despite this wonderful packaging, the cover was victim to damage

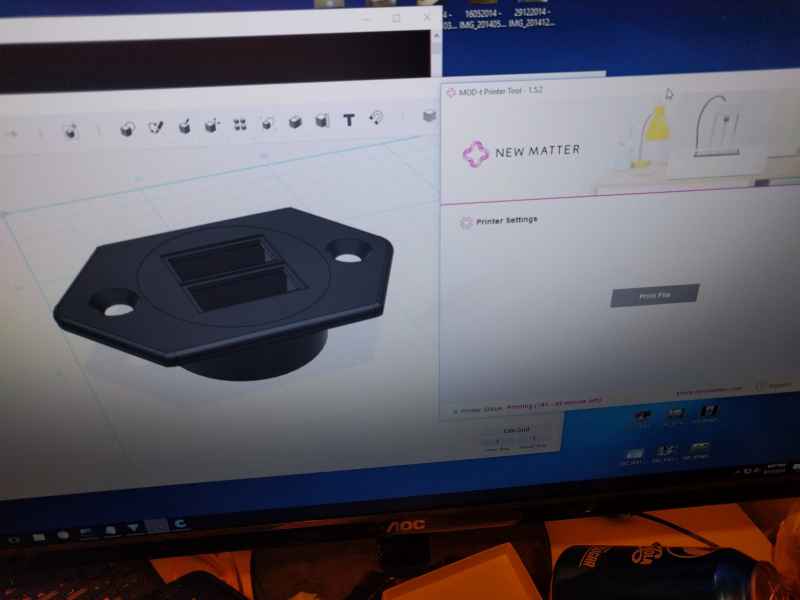

While most of these bugs were firmware related, some were getting the software slicer settings right. At the time, I was using New Matter's web store at store.newmatter.com. It was relatively easy to add your own stl files to print, but the website was about as mature as the printer. I quickly tried slic3r and my prints turned out far worse with this slicer. Being very ne to 3D printing, I didn't even understand what I could tweak to make everything print correctly. I then found out the New Matter's own store uses Cura on the back end (or at least did) and we were able to get a working profile to use that slicer. And that's what I have been using ever since. Sorry New Matter store; nothing personal.

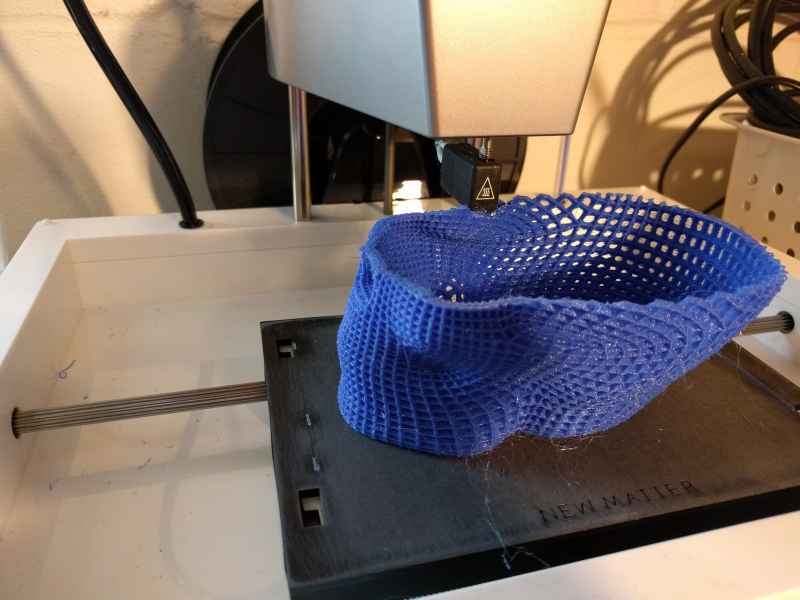

The printer starting a print

The printer starting a print

Failed Prints

My biggest issue I was having with this printer was failed prints. Now that I had the slicer working fairly consistently, the printer itself was showing more issues that were firmware (or hardware) based. Issues like the hot end bury itself into the print tray or extruding so much plastic that it welds itself to the tray. I also had the hot end completely fall off and release plastic spaghetti all over the inside of the cover. There were also issues with the print bed shifting or jumping, due to it's unique design. Most of these issues have been resolved and I hadn't had problems printing beautiful objects.

Some examples of print failuresThese growing pains were expected. As I stated before, I was more or less a guinea pig for this new printer. I found a couple forums and quickly starting learning how to tweak and best use this printer. I found some prints on Thingiverse that helped to stop the bed from jumping, to help with the cooling of parts, and to reduce noise by completely closing off the cover. There aren't as many upgrades as say for the Anet A8, but there needed to be a few.

The Good

I've owned this printer for almost 2 years now and I still like it. Not because it's my only 3D printer, but because it works well. It may have a small build volume at 100 x 120 x 150mm, but it's a budget printer from 2 years ago. I had Cura tweaked to what I consider perfect settings and can say with 99% confidence that it will print correctly. There still seems to be a minor firmware bug were x-axis shifting exists, but I don't experience it a lot. So without further bashing or being too critical, here are some of my prints that come out great.

Some of my successful printsWhile these are nowhere near everything that I have printed with this 3D printer, these are the examples that were most readily available to me. Through the use of this printer, I have learned 3D modeling and design and much more about FDM printers. I think it's time for something new though. I need a bigger print volume for some of my designs and would like to try different material at some time. I forgot to mention this printer only uses 1.75mm PLA.

Conclusion

At the time of this post, you can purchase the New Matter MOD-t for $299. This price has come down from the $399 price of just a few months ago. At it's current price point, I believe this printer is a completely viable option to get started with 3D printing. You can get DIY kits for cheaper, but you don't have to assemble the MOD-t. It's pretty much ready as soon as you plug it in. If you are looking for an affordable first printer, this may be the printer for you.

Pros

- Fully Assembled

- Print from Store (no experience)

- Good Quality (down to 0.1mm layers)

- Removable Build Tray

- Self Contained (with cover)

- Relatively Quiet

Cons

- Small Build Volume (100 x 120 x 150)

- Need USB or Wifi Connection

- Slower Print Speeds

- Firmware Bugs still Present

- Slow Support (But good support)

- PLA Only